I’ve always been a fan of technology, I should hope so, I’ve worked in technology roles all my career.

But why a laser cutter, how did I end up with a one? Two things drove me to my purchase.

- I can’t cut out small pieces in card or paper to save my life. I’ve tried and I’m always unhappy with my results.

- Early onset arthritis means I end up with intense pain in my fingers and hand joints if I do too much of the same thing, like cutting card.

I thought about a Cricut machine, but from what I read that has quite a few limitations. So after a rabbit hole journey through the internet, I found myself looking at laser cutters.

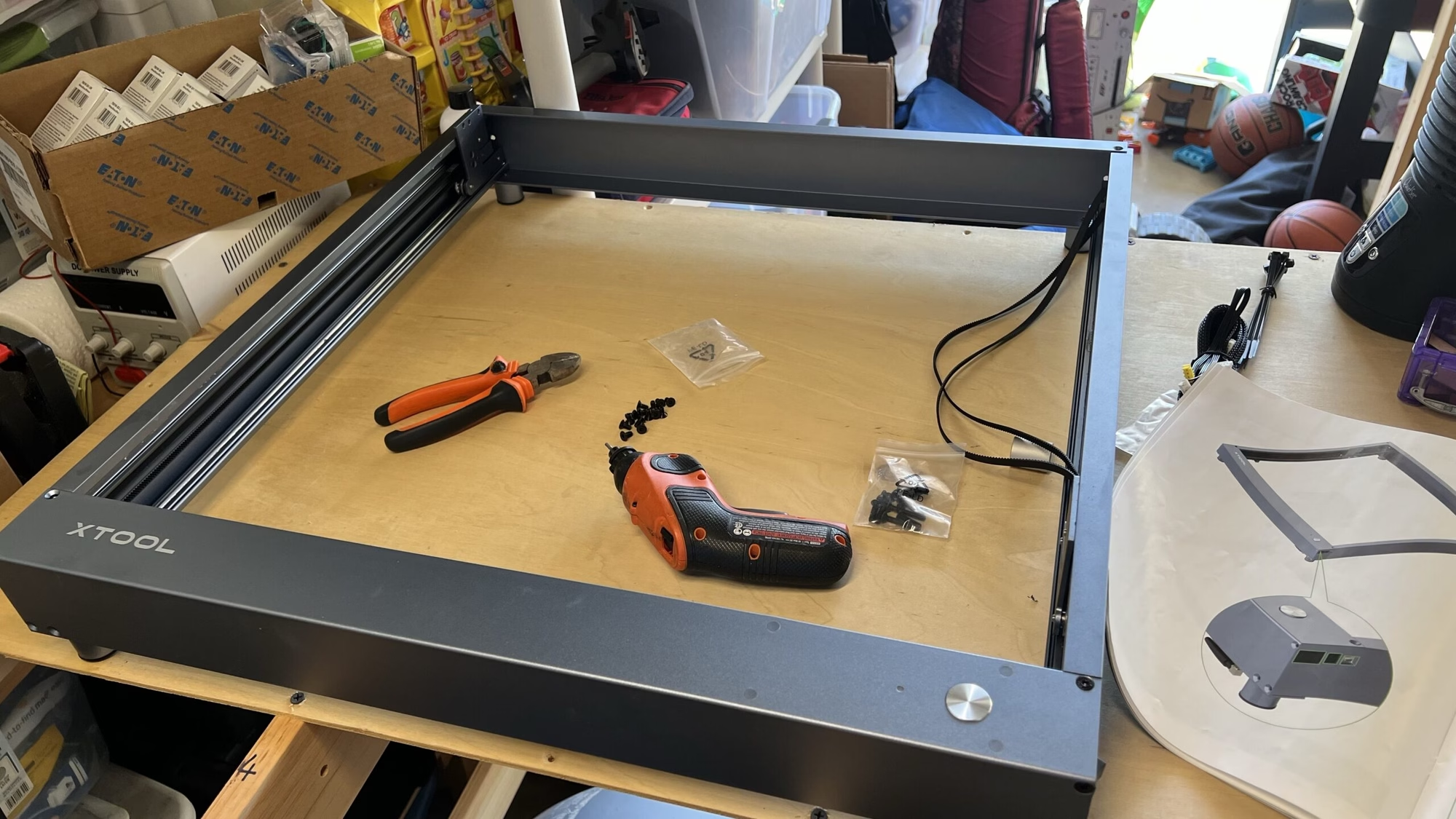

I settled on the XTool D1 10Watt. I tried the 5Watt, but it took several passes to go through some materials. The 10W burns through with no problem.

Here is the US Amazon link to the Laser Cutter.

Here is the UK Amazon link to the Laser Cutter

It comes in kit form, but anyone who is used to buggering about with model railways won’t have a problem putting it together. The instructions are very clear and well thought out. It took me about 1 hour.

It comes in kit form, but anyone who is used to buggering about with model railways won’t have a problem putting it together. The instructions are very clear and well thought out. It took me about 1 hour.

Finished…

There is something very James Bondish watching the laser move across the board…

The Trenton Bus Depot build was the first thing I cut out on the laser. I actually started cutting out the kit by hand in card. But after 2 nights of painful hands and uneven, not level walls, I stopped. That’s when I began my search for an alternative.

Everything was cut out on the laser

I use 2mm plywood and it’s as sturdy as a rock.

Cutting out roof trusses

Windows, lintels, tool chests, all laser cut

The Laser also did the masonry letters in “Etch” mode

The Bus Depot was designed in Inkscape taking cues from the Scalescenes kit. I learnt a lot in that process, and I will definitely do things differently in future builds. Like making interlocking cutouts on the sides of the walls to get a perfect alignment and fit. I did that on the next build which was Manvers Court Tower Block.

For the Tower Block build, the laser does things I simply cannot do. The 4 walls all lock together perfectly straight, the laser cut out 84 windows and 84 window frames in minutes, each one is perfect.

I can’t even get close to that. What would have taken me several nights and still would have been crap (to me anyway) took minutes.

I know these laser cutters aren’t cheap, but I got a deal on Amazon and I had several Amazon gift cards lying around so that covered most of it.

For me it’s worth it. It saves me days, I don’t get disheartened and my hands don’t hurt.

The learning curve isn’t too bad. The free application Inkscape is used to draw the designs, then you load that file into the XTool software, and then send it to the laser. You can import a Scalescenes PDF into Inkscape, and by removing most of the outer layers, end up with the bare walls, which can be sent to the laser.

I’ve just done that exact thing with the Scalescenes low relief warehouse kit. More of that build here.

The short video below shows the laser in action cutting out some windows and doors.

I know it’s not for everyone, but for me it’s fantastic.

I’m sure some people will say it’s not real modeling, but hey, that’s ok. As far as I’m concerned, Rule Number 1 applies. It’s my layout and I can do what I want.

Thanks for reading, if anyone is interested in the SVG files that make up either the bus depot or the tower block, drop me a message and I’ll happily send them over.