Is 3D Printing Right For Your Layout?

I know this technology isn’t everyone’s thing, but stick with me for a minute.

3D Printing has been around for a few years now. The machines have reached a price point that is attainable for a lot of people. Yes, I know $250 (£192GBP) is still a lot of money, but considering that a single plastic kit can be over $60 (£46)….

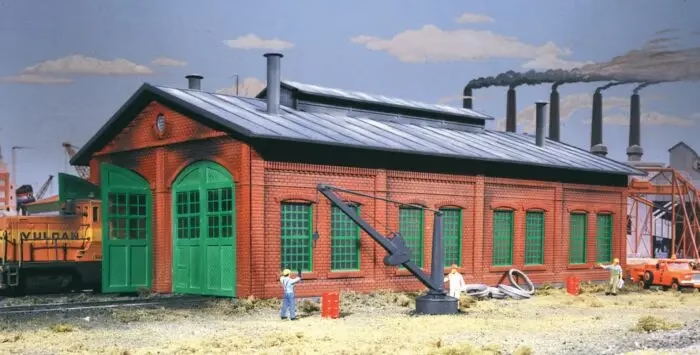

This Walthers Engine Shed Costs $55 (£43) If you buy between 4-5 kits similar to this, you’ve paid for the 3D printer. Then when you add the cost of all the other detailing parts, you will have covered the cost easily.

Here’s another example. This Bachmann Coach Washing Plant retails in the UK for £35GBP ($45)

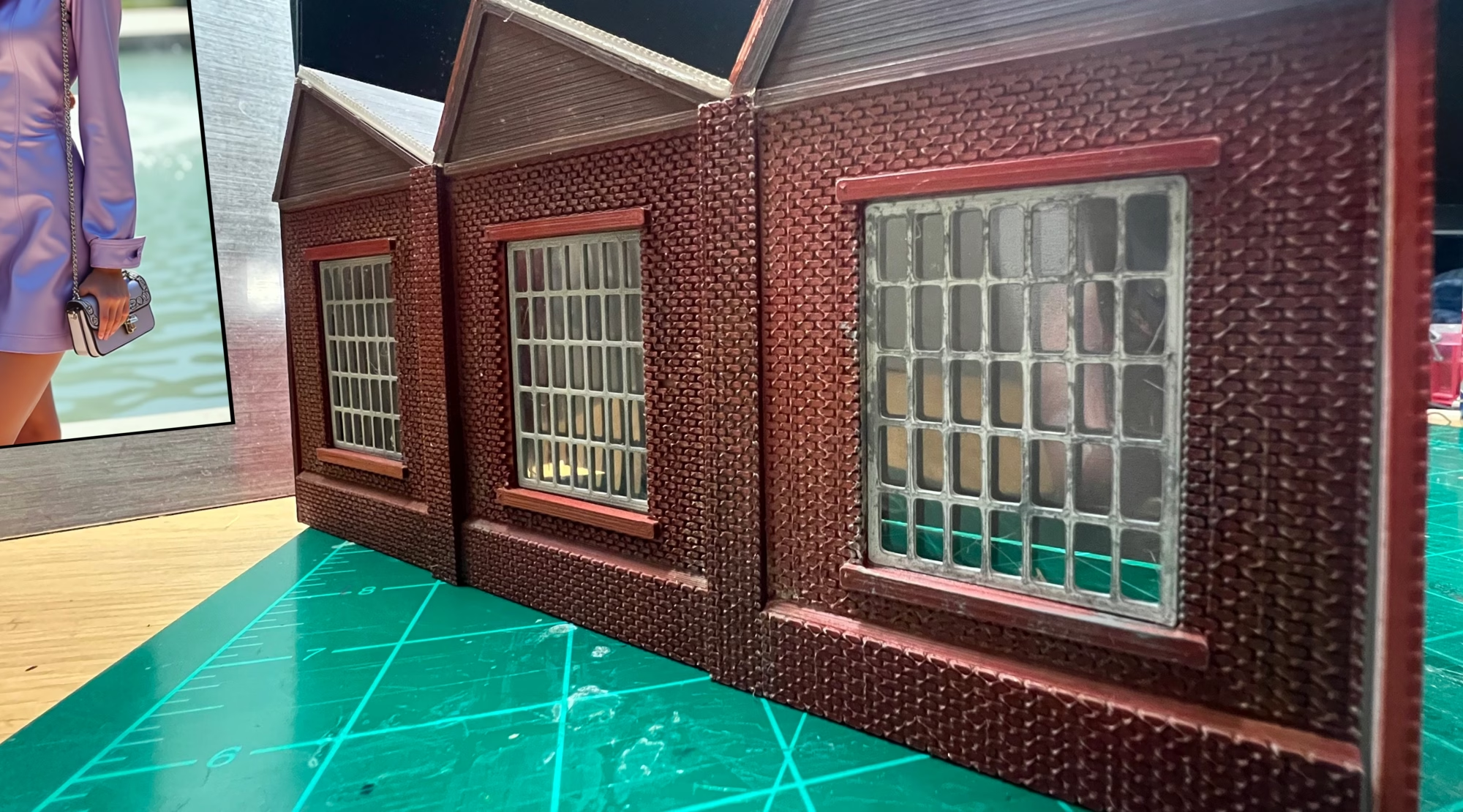

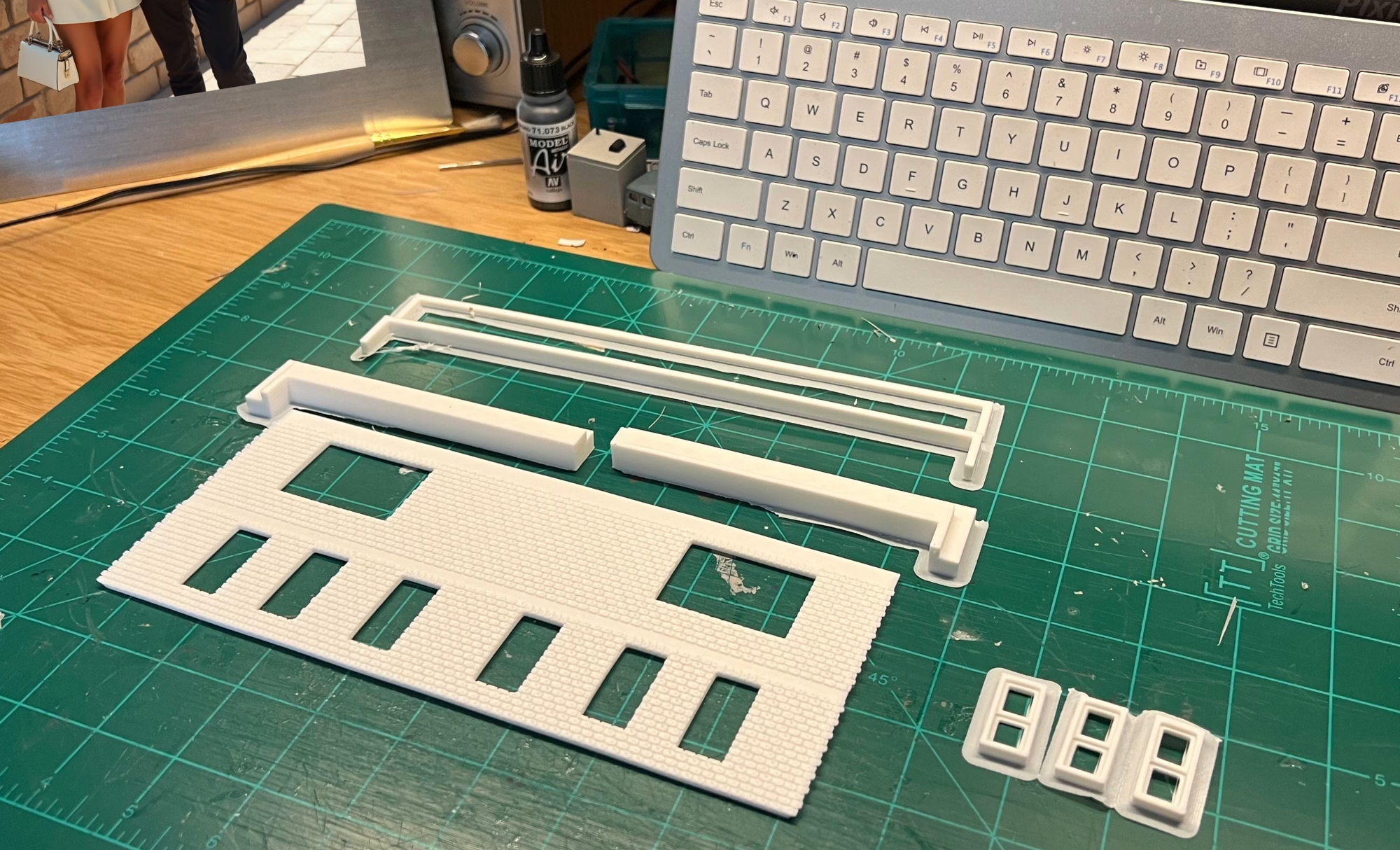

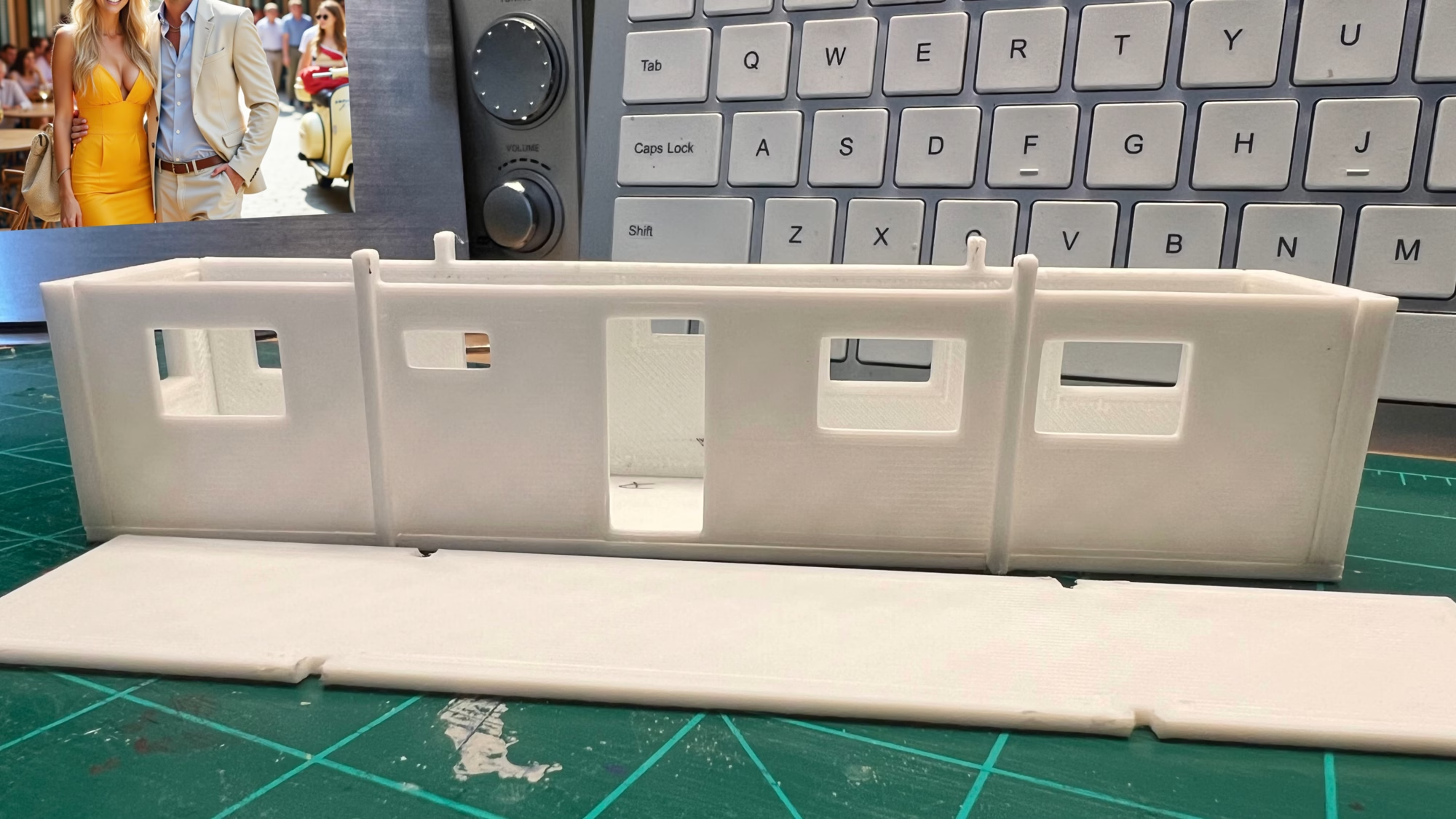

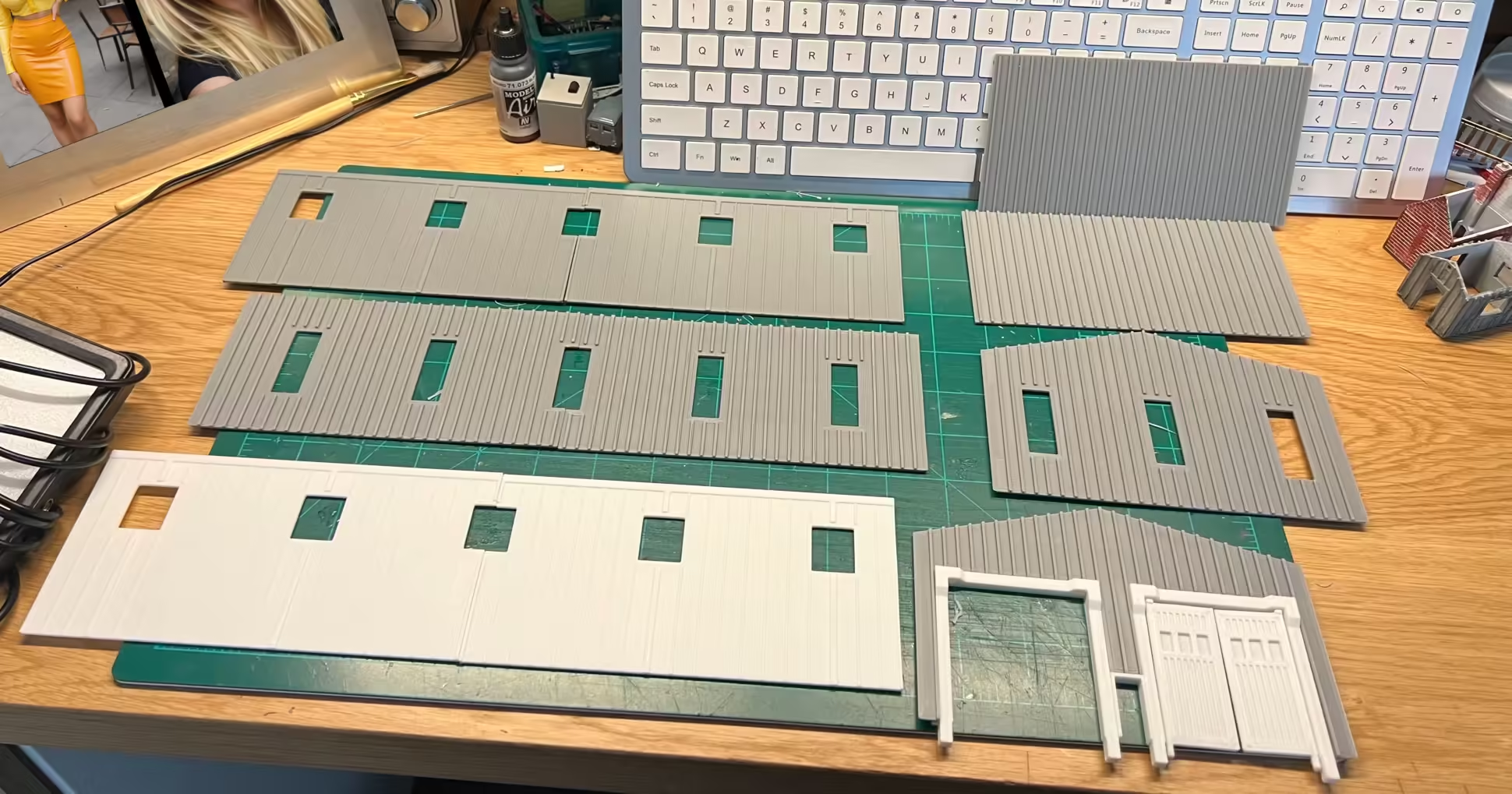

I created my own version in Tinkercad and 3D printed this: (I haven’t finished detailing it yet, but you get the idea) The plastic filament cost me about $3 (~£2.30)

That’s not modeling.

…I know there will be a lot of modelers who will be shouting at the screen saying something like:

- It’s not real modeling.

- I make everything out of household rubbish and coffee stirrers from Starbucks.

- It’s elitist nonsense.

..and that’s OK, rule number 1 applies.

But for those of you who are considering this exciting new aspect to the hobby, hopefully, this post will give you some food for thought.

Here’s my view. Everything changes, nothing stands still. I know a lot of us build layouts that re-create a certain period in time, but I don’t have to use tools from the 1970’s to create a 1970s-themed layout.

This hobby like many hobbies is struggling to attract new blood. Buggering about soldering, sawing, painting and general “tinkering” to a lot of people is just too much hard work.

They can sit in front of a TV and have very realistic simulations and games that trigger neural endorphins that watching a Class 8 diesel go around a circle just cannot. (well, to most people anyway)

3D printing is here to stay and I think it’s a fantastic addition to the tools and processes that I use in this hobby, and maybe, just maybe, it could attract someone into the hobby.

Types of 3D Printers

There are basically two types of 3D printers. Filament and Resin. Here is a simple explanation of the difference between the two types.

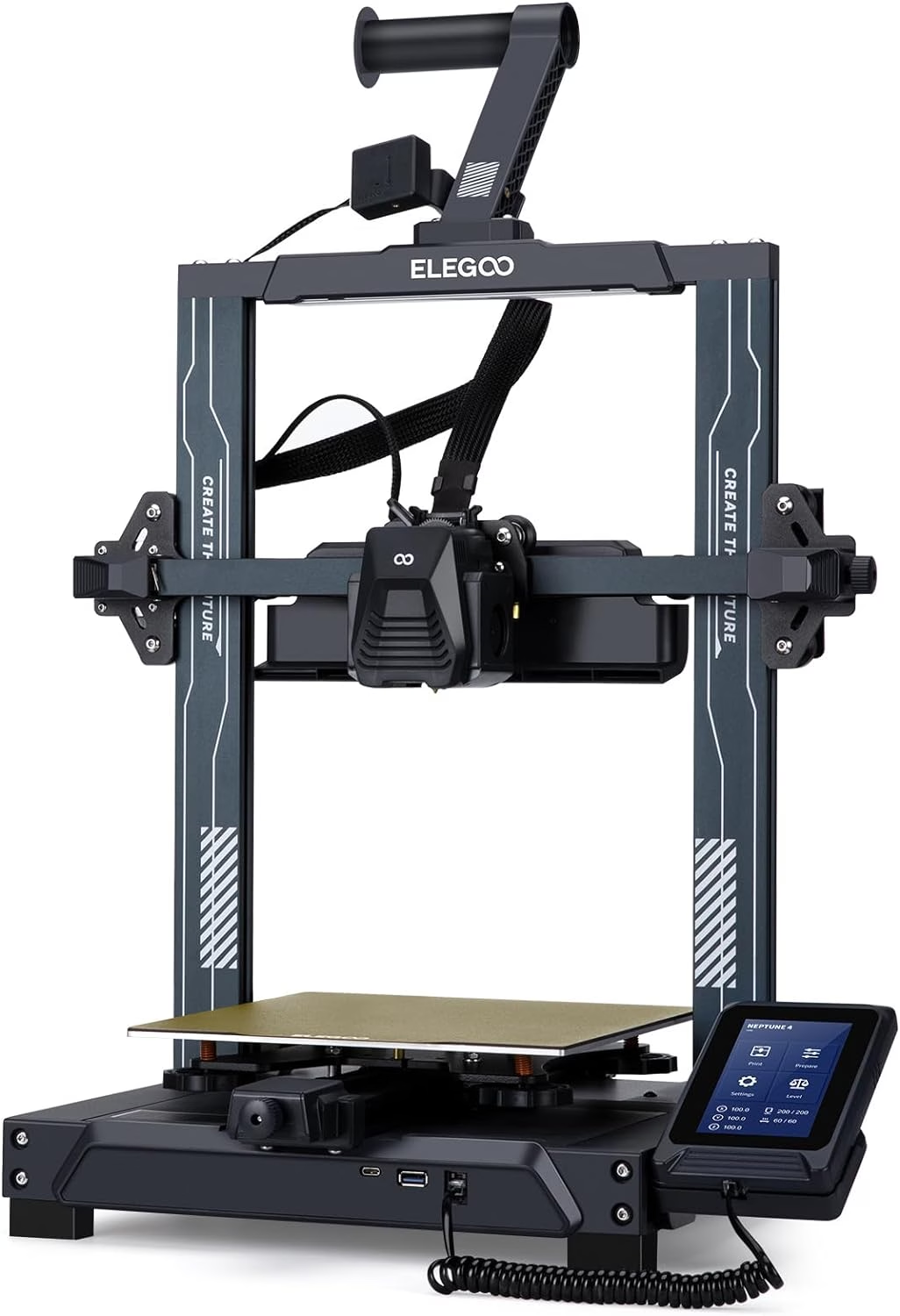

Filament 3D Printers (FDM/FFF):

This is the model of the Filament printer I own. I can state that it’s REALLY easy to use and gives great results. Check out the structures, custom parts and detailing items I’ve created on this 3D Printer.

US Amazon Link: https://amzn.to/3YbMpKH

– Material Used: Plastic filament (like a thin string of plastic).

– How It Works: The printer heats the filament and extrudes it through a nozzle, layer by layer, to build the object.

– Common Uses: Larger, less detailed objects, like prototypes, parts, and simple models.

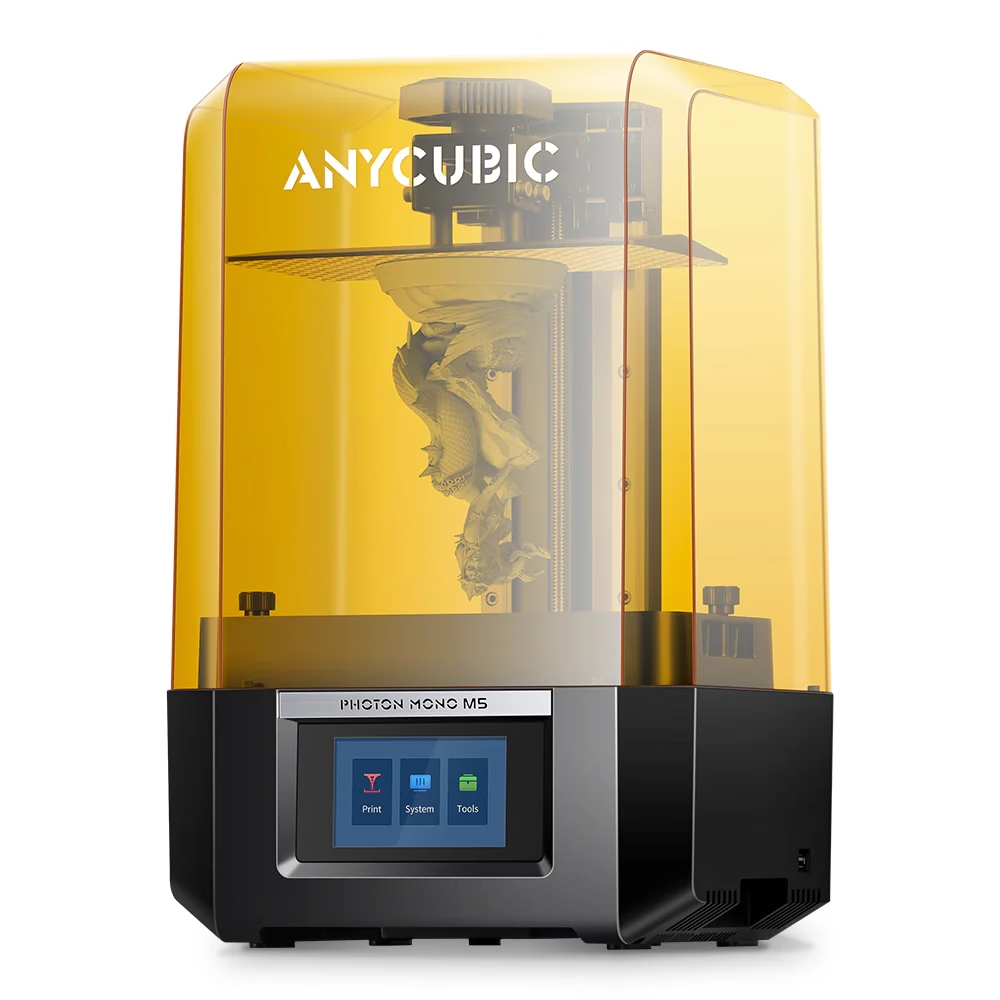

Resin 3D Printers (SLA/DLP):

This is the model of Resin printer I have. It creates incredibly detailed items.

US Amazon Link: https://amzn.to/3zJ27TA

– Material Used: Liquid resin.

– How It Works: The printer uses a light source (like a laser or UV light) to harden the resin layer by layer, creating the object.

– Common Uses: Smaller, highly detailed objects, like miniatures, jewelry, and detailed models.

In summary, filament printers use heated plastic to build objects, while resin printers use light to harden liquid resin into detailed shapes.

The great thing about 3D printers is that if you can think it, you can pretty much create it.

3D printing has become a valuable tool in model railroading, offering a wide range of applications to enhance layouts and rolling stock.

Here are 10 examples of how 3D printing can be used in model railroading:

- Custom Rolling Stock:

– Create unique freight cars, passenger cars, and locomotives that aren’t available in commercial kits.

- Detailed Scenery Elements:

– Print intricate buildings, bridges, and other architectural structures to enhance the realism of the layout.

- Track Components:

– Produce custom track pieces, switches, and crossings tailored to specific layout needs.

- Locomotive and Car Parts:

– Manufacture replacement parts for damaged or missing components of locomotives and rolling stock, such as couplers, wheels, and handrails.

- Figures and Accessories:

– Print detailed figures of people, animals, and other accessories to populate the layout and create realistic scenes.

- Unique Terrain Features:

– Create custom terrain features like mountains, tunnels, and rock formations that fit perfectly into specific layout sections.

- Signage and Signals:

– Produce custom signs, signal posts, and other railway signaling equipment to match specific prototype or fictional designs.

- Scenic Details:

– Print small scenic details like benches, street lamps, fences, and other urban or rural fixtures that add depth to the scene.

- Stationary Equipment:

– Create detailed stationary equipment such as cranes, water towers, and fuel tanks, adding authenticity to industrial or maintenance areas.

- Prototyping and Testing:

– Use 3D printing to prototype new designs and test them before committing to final production, allowing for adjustments and improvements.

These examples demonstrate the versatility and potential of 3D printing to customize, repair, and enhance model railroad layouts and equipment.

This is a real example of something I have 3D printed on my layout.